English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

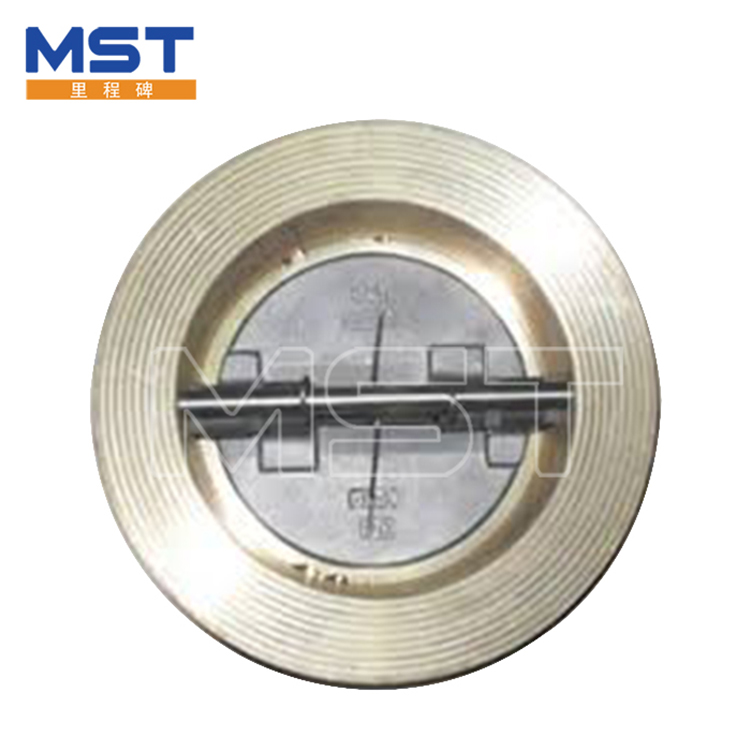

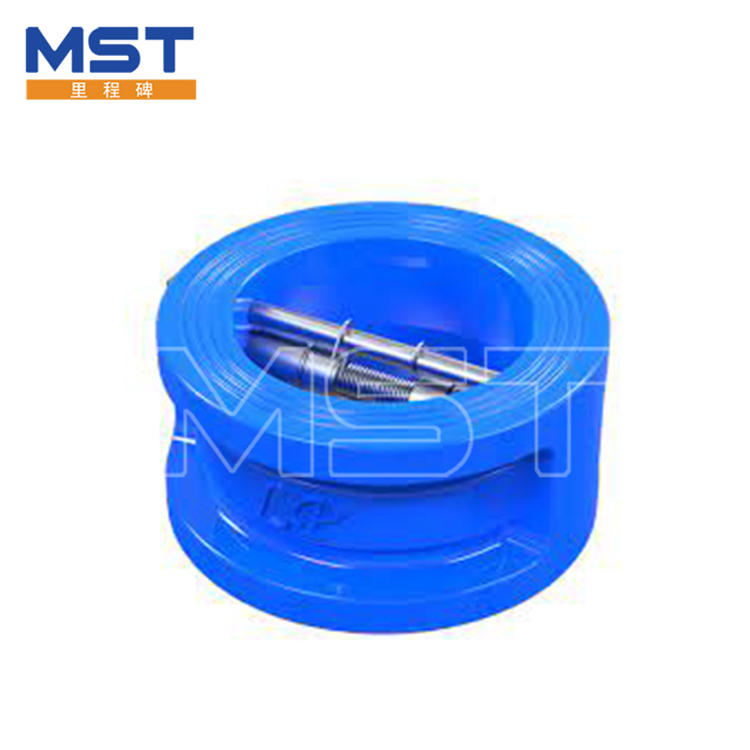

Dual Plate Wafer Check Valves

Send Inquiry

1.Introduction of Dual plate wafer check valves

Dual Plate Wafer Check Valves have been the preferred choice due to their proven reliability and low pressure drops. MST produced Dual plate wafer check valves are tested to API 598 and must meet or exceed all applicable API, ANSI and ASTM Standards.

2.Technical Data of Dual plate wafer check valves

|

Type of Valve |

Dual plate check valve |

|

DN |

DN50~DN300 |

|

PN(MPa) |

PN10, PN16, Class 125 |

|

Design Temperature Range |

-15℃~425℃ |

|

Connection type |

Flanged |

|

Applicable Medium |

Water, oil, and various corrosion medium |

3.Dual Plate Wafer Check Valves offer some impressive advantages over other types of check valves.

1) Low Pressure Drop

Dual plate wafer check valves have larger open area than other designs, thus reducing pressure drop compared to swing, lift or other check valves.

2) Light Weight:

Dual plate wafer check valves reduces weight by 80–90% compared to conventional Flanged check valves.

3) Lower Cost

Light weight, compact profiles and the elimination of flanges allows DPW check valves to be manufactured more economically than other designs, especially as pipe diameters increase.

4) Alleviates Water Hammer

Our spring activated discs are designed to close our valves quickly. This assures high performance, eliminating chatter and creating dynamic responsiveness in a non-slam design.

5) Simple Installation

Dual plate wafer check valves easier to install, remove and replace in both new and existing piping systems.

4.Variety of Configurations of Dual plate wafer check valves:

MST Valve offers a wide variety of wafer bodies in different styles and materials. These can be assembled with any one of our standard disc, optional spring and elastomer seal choices to make a valve that exactly fits your application. Contact Ranee if you would like a quote on any of these options.

5.About MST

6.Welcome to Contact Us

Welcome to vist our website about more valve, and please feel free to contact us if you have any questions.

Sale manager: Ranee Liang

Email: ranee@milestonevalve.com

7. FAQ