English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

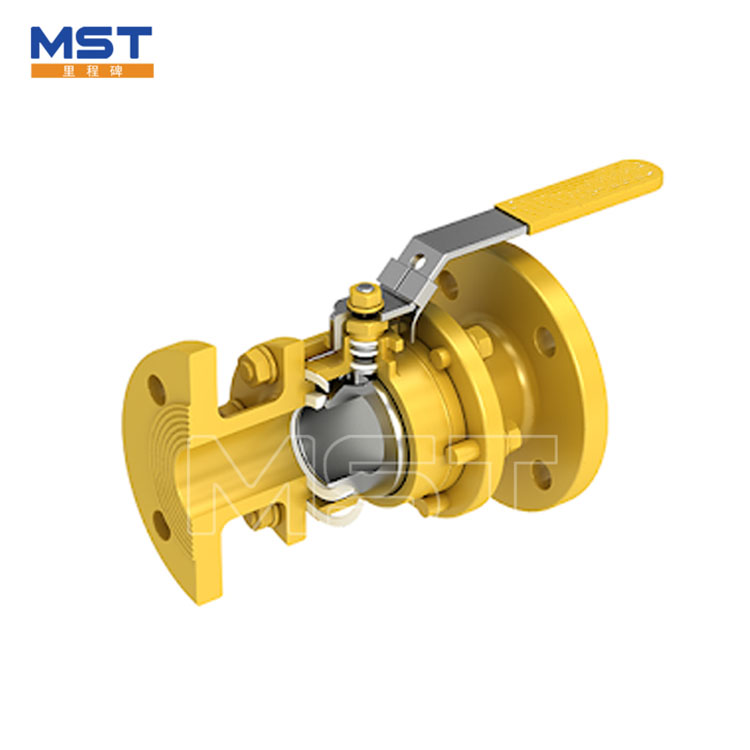

Gas ball valve

Send Inquiry

Milestone is a professional China Gas ball valve manufacturer and supplier, if you are looking for the best Gas ball valve with low price, consult us now!

Gas ball valve refers to long-distance pipelines suitable for natural gas, artificial coal-to-gas, and liquefied gas, and urban gas transmission and distribution network. It is manufactured in accordance with the requirements of GB/T12237-2007, GB/T12224-2005 and related valve standards. Ball valves with fire-proof, anti-static, safe, reliable, and high anti-corrosion performance. It can be specially used for natural gas, coal gas, liquefied gas and other gas and non-corrosive gas pipeline control and flow control.

Gas ball valve product parameters

Type of Valve

Gas ball valve

DN

DN15~DN250

PN(MPa)

1.6~4.0Mpa

Design Temperature Range

-15℃~425℃

Connection type:

Flanged, Butt weld

Actuator type

Manual drive, Pneumatic, Hydraulic or electric Actuator

Sealing

Metal Hard Seal

Applicable Medium

oil, gas, and various corrosion medium

Spare Parts

Material

Body

Forged steel, Cast steel, Stainless Steel

Ball

Forged steel, Cast steel, Stainless Steel

Stem

Forged steel, Stainless Steel

Seat ring

Forged steel, Stainless Steel

Seat

PTFE, RPTFE, NYLON, PEEK, PPL, POM, DEVLON

Gasket

Stainless Steel, flexible graphite spiral wound

Packing

PTFE, flexible graphite

Gas ball valve product features

1) Gas ball valve anti-static and fireproof device; Gas ball valve has a spring electrostatic discharge device to achieve the purpose of removing static electricity. Avoid static sparking and ignite flammable media to ensure system safety.

2) Gas ball valve uses PTFE as a seal, which has good lubricity and elasticity, small friction with the ball, and long service life;

3) Gas ball valve must ensure that there is no leakage; the leakage volume of natural gas valves is very strict. Generally, buried and more important valves are all welded with valve bodies. In order to ensure the sealing performance of pipeline valves, the sealing pair is required to have excellent corrosion resistance, wear resistance, self-lubricity and elasticity.

4) The main sealing and wearing parts of Gas ball valve pipeline valves such as valve seats and other parts require long life. Generally, the service life of main pipeline valves is more than 30 years.

Gas ball valve produced by MST is suitable for long-distance pipelines of natural gas, artificial coal-to-gas, liquefied gas, and urban gas transmission and distribution network. It adopts a typical floating ball two-piece structure, full-diameter design, stainless steel sphere, and structure. Simple, convenient installation, labor-saving opening and closing operations, easy maintenance, safe, reliable, and high corrosion resistance. It has a wide range of applications and is well received by users.