English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

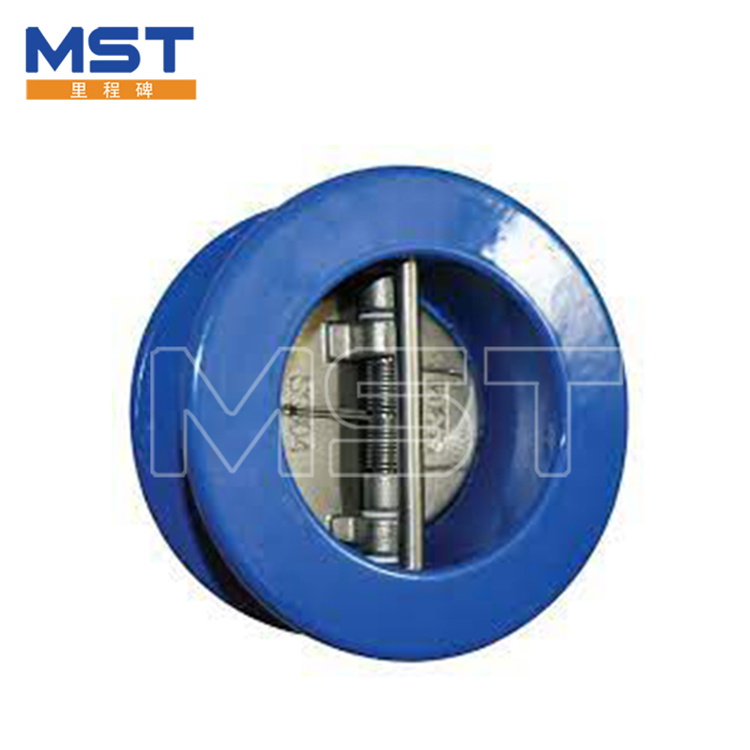

Wafer Check Valves

Send Inquiry

1.Introduction of Wafer check valves

The Wafer check valves are self-acting and fast-closing valves which prevent a working medium from flowing back in a pipeline. They are used in order to prevent from backflow the pumps, fans etc. TWafer check valve is not a shut-off valve.

2.Working medium of Wafer check valve:

Water, air, steam and other non-aggressive liquids and gases. The fluid flow direction may be only from one side of the valve. The fluid flow direction is marked with an arrow on the valve body.

3.Technical Data of Wafer check valves

|

Type of Valve |

Dual plate check valve |

|

DN |

DN50~DN300 |

|

PN(MPa) |

PN10, PN16, Class 125 |

|

Design Temperature Range |

-15℃~425℃ |

|

Connection type: |

Flanged |

|

Applicable Medium |

Water, oil, gas, and various corrosion medium |

4.Some precautions for wafer check valve

Working temperature of Wafer check valve:

Service temperature depends on the material of seals. - 46°C up to 260 °C

Technical description of Wafer check valve:

The two valve discs, eccentrically embedded, have springs which force the valve to close in case no pressure is available.

Operation of Wafer check valve:

The Wafer check valve are automatic, quick-acting valves. Movement of the discs is controlled by the flowing fluid.

5.Testing of Wafer check valve:

Wafer check valves are tested for strength and leakage, functionality and tightness acc. to EN 12 266 section 1, leakage grade is D (grade B on request). Connection to piping flanged ends acc. to EN 1092-1, EN 1759-1 or GOST 12815-80 face to face dimension acc. to EN 558 welded ends acc. to EN 12 627 face to face dimension acc. to EN 12 982

6.About Milestone Pump Company

Welcome to vist our website about more valve, and please feel free to contact us if you have any questions.

Sale manager: Ranee Liang

Email: ranee@milestonevalve.com

8. FAQ